Pneumatic piston cut-off valve

Pneumatic piston cut-off valve

Nominal diameter: DN20mm ~ 200mm

Nominal pressure: 0.4 ~ 0.6MPa

Temperature: -40 ℃ ~ 450 ℃

Flange Standard: GB4216-84 cast iron flange flange GB9113-88, JB / T79- 94

Product description:

Pneumatic

piston cut-off valve (referred to as the piston cut-off valve), is the

implementation of pneumatic actuator unit in the instrument cluster. It

receives signals from regulating instruments to control the shut-off of

fluid in the process piping and to switch the flow path on or off. The

product has the advantages of large operating force, novel design of the

valve body, small flow resistance, large rated flow coefficient, large

allowable pressure difference and excellent sealing performance. Thus

widely used in petroleum, chemical, metallurgy, electric power, textile

and other industrial sectors of the automatic control and remote control

system.

Features:

1, Shut-off

valve adopts multi-spring actuator and adjusting mechanism to connect

with three columns, the whole height can be reduced by about 30% and the

weight can be reduced by about 30%.

2, the valve body designed by the principle of fluid mechanics such as

cross-section low flow resistance flow channel, the rated flow

coefficient increased by 30%.

3, the valve part of the seal has two types of tight and soft seal,

close-type surfacing carbide, soft seal for the soft material

production, sealing performance when closed.

4, balanced type trim, improve the allowable pressure drop off valve.

5, the bellows sealed type of valve stem to form a complete seal, blocking the possibility of media leakage.

6, piston-type actuator, operating force, the use of large pressure.

Part Information:

Pneumatic

piston cut-off valve by the pneumatic piston-type actuator and the

straight stroke adjustment mechanism of two parts, the middle by the

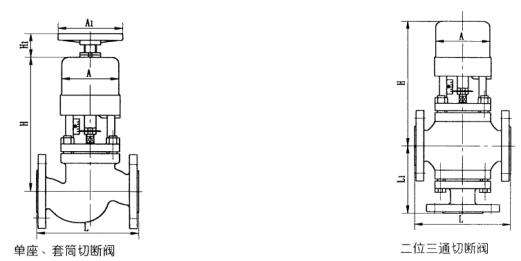

bracket connection. According to the type of adjusting mechanism,

pneumatic piston-type cut-off valve can be divided into three types:

straight-through single-seat shut-off valve (ZSQP type), straight

through sleeve shut-off valve (ZSQM type) and two position three-way

shutoff valve (ZSQN type) Pneumatic piston actuator has a single role

(spring reset) and double-acting (double intake) two. Single-acting

actuator, the role of the whole machine can be divided into gas-off

(horizontal pipe connected) and open air (horizontal pipe

disconnected). Pneumatic piston cut-off valve has a hard seal and soft

seal two seal forms, respectively, for different temperature and

pressure.

When the signal pressure is zero, the spool is in its initial state

(normally open or normally closed) due to the preload of the spring

(only for single action). When the actuator receives the signal pressure

(0.4 ~ 0.6MPa), the piston produces thrust, compress the spring, push

the push rod, the valve body, the spool moves to the extreme position,

the valve fully open or fully closed. To achieve the media inside the

pipeline, cut off or switch between the control of the

pipeline. Equipped with two three-way solenoid valve, the piston-type

shut-off valve control more convenient and simple.

Technical Parameters:

Nominal diameter DN (mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | ||

Rated flow coefficient Kv | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 | ||

Rated travel (mm) | 8 | 12 | 20 | 25 | ||||||

Cylinder diameter (mm) | 75 | 100 | 150 | |||||||

Allow leakage | Hard seal (1 / h) | Single-seat, three-way: 1.2X10 -7 X valve rated capacity Sleeve: 5X10-6 X valve rated capacity | ||||||||

Soft seal | Level VI | |||||||||

Working temperature (℃) | -20 ~ 200 -40 ~ 450 | |||||||||

Nominal pressure PN (MPa) | 1.6 4.0 6.4 | |||||||||

Allow pressure drop (MPa) | ZSQP | Single role | 1.16 | 0.66 | 0.38 | 0.6 | 0.39 | 0.47 | 0.31 | 0.20 |

Double role | 6.4 | 5.0 | 2.8 | 3.3 | 2.13 | 2.71 | 1.75 | 1.11 | ||

ZSQM | Single role | Nominal pressure | ||||||||

Double role | ||||||||||

ZSQN | Single role | 0.89 | 0.57 | 0.35 | 0.56 | 0.36 | 0.45 | 0.30 | 0.20 | |

Double role | 5.2 | 3.22 | 2.03 | 2.27 | 1.46 | 2.00 | 1.32 | 0.85 | ||

Signal pressure (kPa) | 0 or 400 ~ 60 | |||||||||

1) The performance indicators of this product are in accordance with GB / T4213-92;

2) If the allowable pressure difference in the table is greater than

the nominal pressure, the nominal pressure shall be taken as the nominal

pressure and less than or equal to the nominal pressure;

3) Value, can be equipped with different cylinders to increase the allowable pressure.

Specifications Weight:

Nominal diameter DN | L | A | H | L 1 | H 1 | A 1 | Weight (Kg) | Signal connector internal thread |

20 | 150 | 130 | 220 | 80 | 115 | 100 | 10 | M10X1 |

25 | 160 | 130 | 220 | 80 | 120 | 100 | 12 | |

32 | 180 | 150 | 235 | 80 | 130 | 100 | 15 | |

40 | 200 | 150 | 235 | 95 | 138 | 120 | 18 | |

50 | 230 | 150 | 240 | 95 | 155 | 120 | 25 | |

65 | 290 | 280 | 250 | 105 | 178 | 160 | 30 | |

80 | 310 | 280 | 260 | 105 | 207 | 160 | 40 | |

100 | 350 | 280 | 265 | 105 | 222 | 160 | 60 |

Connection standard:

· Flange standard: Cast iron flange GB4216-84 Cast steel flange GB9113-88, JB / T79-94

· Flange sealing surface type: PN16 convex PN40, 64 concave surface, the body is concave

· Structure length: GB12221 -89

· Actuator signal interface: M10X1

* Body flange and flange end distance can be manufactured according to user-specified standards.

Such as: ANSI, JIS, DIN and other standards

◆ Ordering Information

When ordering, please provide the following information:

· regulating valve name, model

· nominal diameter (mm)

· Nominal pressure (MPa)

· Rated flow coefficient (Kv)

· inlet pressure

· Cut off the pressure

· Name of the medium

· Working temperature and range

· The whole mode

of action · Valve body, valve trim and packing material

· With accessories

· Other special requirements